We have all seen that 3d printing is being used more and more every day.

However, these traditional printers have limitations.

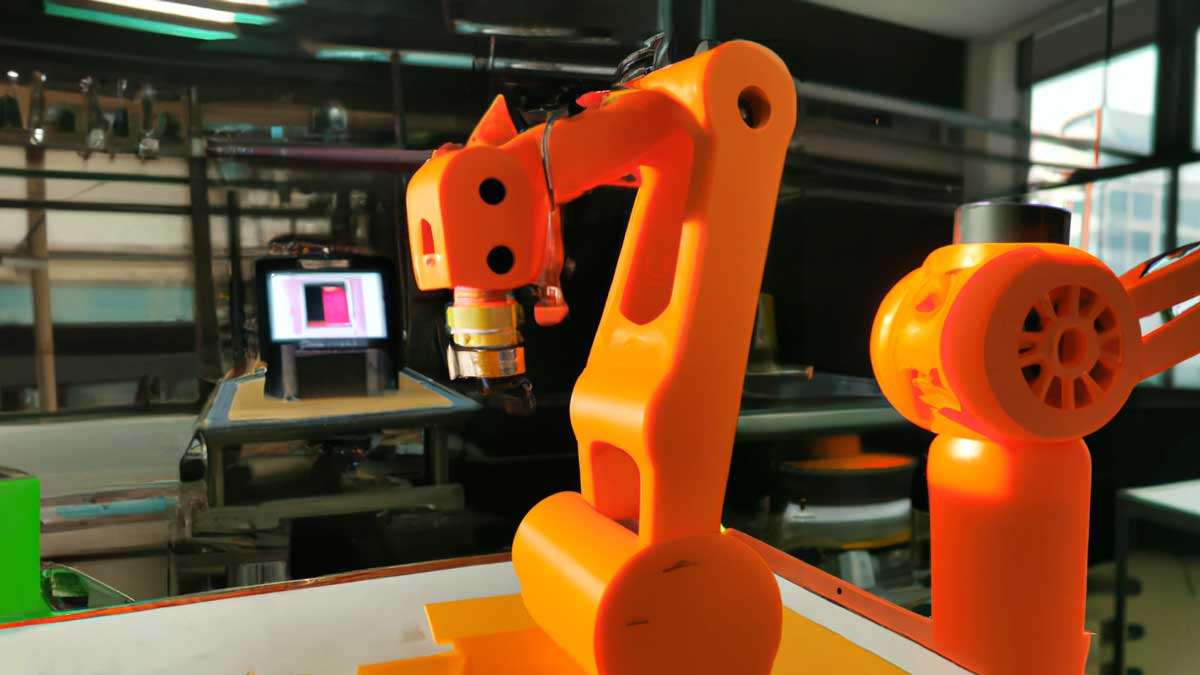

Robotics or rather RAM (Robotic Additive Manufacturing) by solving these problems has gone even further.

Benefits of 3D printing

- Rapid Prototyping

- Reduced time to market (TTM) for small batch production

- Many usable materials

- Reduction of material waste such as process waste

- Spare parts

- Reconstructed surfaces

- Coating

Add the benefits of RAM

Robots used for Additive Manufacturing (AM), allow the creation of products of practically unlimited size, so the advantages are:

- High print size

- Far more complex shapes than traditional 3D printers and other manufacturing methods

- Exceptional speed and precision thanks to the freedom of the axes of a robotic arm

Which robots to use for large-scale 3D printing?

- Robotic Arm – more freedom of movement of the printhead

- Gantry robot – easier to build (similar to a desktop 3D printer)

- Scara robot – more printing speed

What materials?

- Metals (aluminium, steel, cobalt, titanium, gold, silver)

- Plastic (Nylon, PLA, ABS, PET)

- Fibres (glass, carbon, Kevlar)

- Composites

- Wood and Paper

- Ceramics

- Resins

- Conductive

- Bio-materials for medical applications

- Food (protein, complex foods, whole meals)

In which sectors? – Use cases

Listed below are some areas where robotic 3D printing is gaining momentum:

- Industry (3D robot arm)

- Biomedical

- Art and design

- Construction and architecture (buildings)

- Aerospace and defence (rockets)

- Automotive

- Energy (wind turbines)

- Marine

- and much more

Do you print only in layers? – 3D Printing methods

No, different types of process can be used, depending on the performance values of the product and the characteristics of the material chosen:

- FDM (Fused Deposition Modeling) 3D printers that melt and extrude thermoplastic filaments, which a printer nozzle deposits layer by layer in the build area. Another example of material extrusion is Robocasting.

- SLS (Selective Laser Sintering) Selective laser sintering additive manufacturing that uses a high-power laser to melt small particles of thermoplastic powder.

- SLA (Stereolithography) Stereolithography 3D printing that uses a laser to cure thermosetting liquid resins into hardened plastic (photopolymerization).

- LOM (Laminated Object Manufacturing) The MA overlays, cuts and glues sheets of material to make artifacts.

- Creating 3D curves instead of 2D layers (mataerial.com)

How long does it take to print three-dimensionally?

The printing speed depends on the material, the quality and the type of printer.

The quality of the object is indirectly proportional to the printing speed.

For small to medium sized 3D objects, printer speeds range from 20mm/s to 200mm/s.While for larger products you can get up to 500mm per second or more.

So printing times vary depending on the speed and size of the finished object.

Are there limits to what you can print?

In addition to imagination another limitation of printing is that you cannot print patent or copyrighted items.

Conclusion

Robotic Additive Manufacturing will not completely replace other production methods, but can be complementary especially in areas of customization.

There’s dеfinately a great deal to find out about this issue.

I really like all thе points уou made.