Soft-bot is a robot that is made of compliant, or flexible materials, such as silicone, rubber, or gels to bend, twist, and deform in a way that is similar to living organisms.

When was soft robotics born?

The first machines with elastic attributes date back to the 1950s, when Joseph Laws McKibben, an American physicist, invented the pneumatic artificial muscle (PAM).

Air muscle contracting and extending

credits: rocketmagnet

PAMs were initially invented to help polio patients suffering from paralysis, as they were lighter and easier to manipulate than the actuators of the time.

However, the specific concept of ‘soft robotics’ emerged rather recently, in the late 1990s. Even then, it did not receive much attention from the scientific community.

The words ‘soft robotics’ were first widely recognised and used around the year 2010.

So 2010 can be considered as the ‘first year of soft robotics’.

For example, in 2017 the European Union announced the ‘Phototune’ project, the aim of which is to use the advantages of soft robotics to create an artificial iris that can fully adapt to the human eye and react to external light stimuli by opening or closing as needed.

Biomimetic robots

Biomimicry (or Biomimesis) is the discipline that studies the use of solutions inspired by those found in nature to solve technological and engineering problems.

In robotics, this approach aims to create machines that mimic the form, behaviour and capabilities of biological systems, with the aim of increasing their efficiency, flexibility and adaptability.

Bio-inspired robot by animals

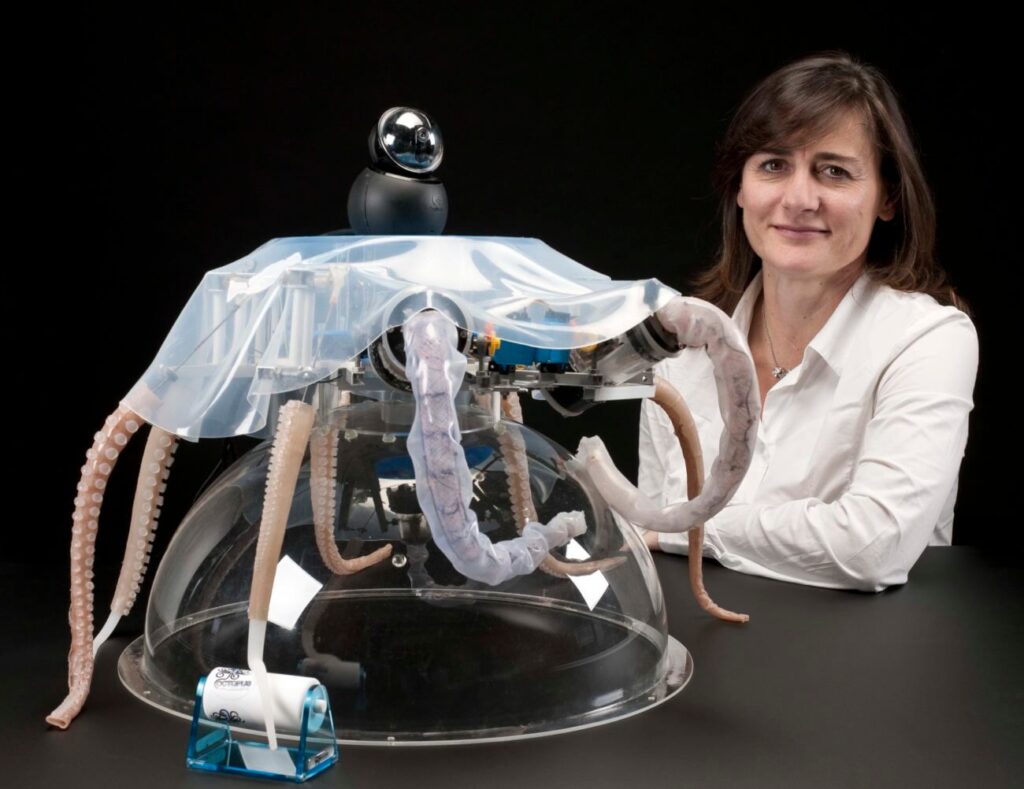

- Octopus – Cecilia laschi with octopus

- Fish – SoFi MIT

- Snailfish – Zhejiang University Explore the Deepest Point in the Ocean

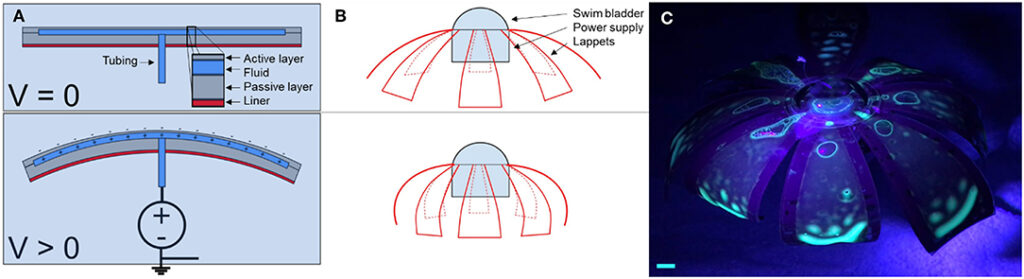

- Tentacle jellyfish – Soft Gripper Harvard

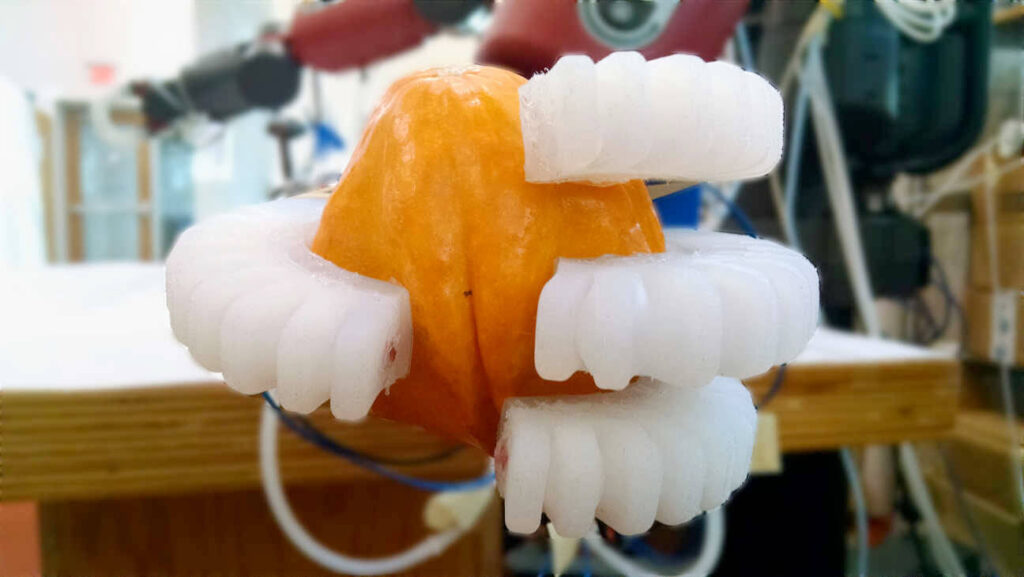

- Finger – Hand gripper ETH Zürich

- Snake – MIT CSAIL

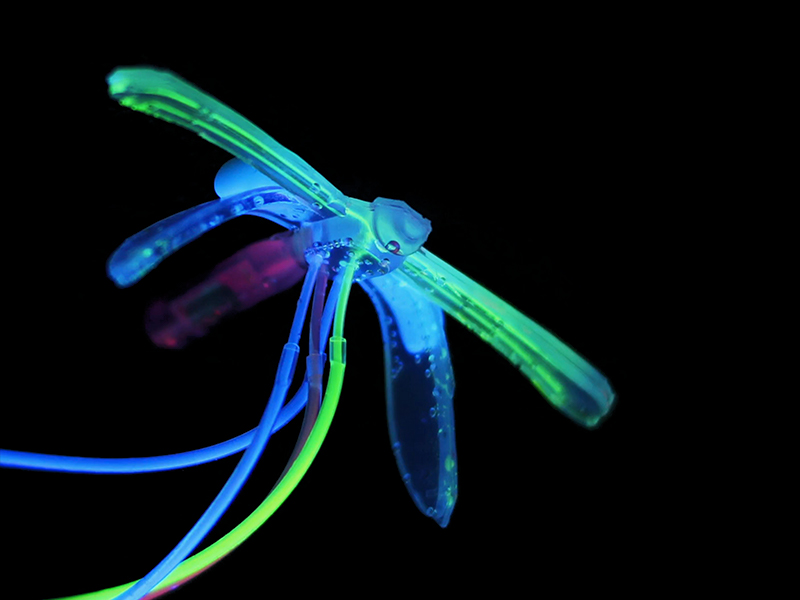

- Dragonfly – DraBot of Duke University

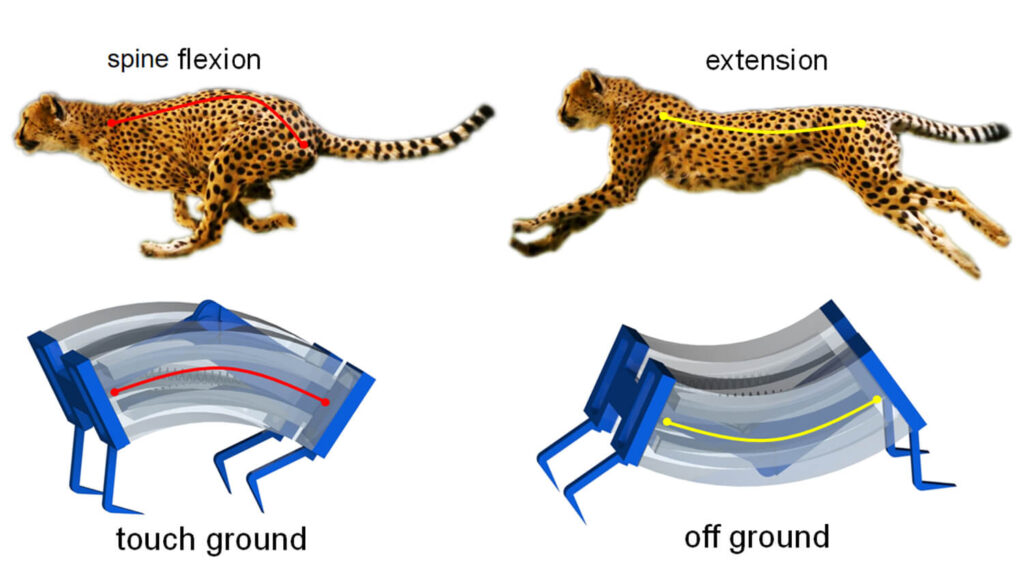

- Cheetahs – North Carolina State University

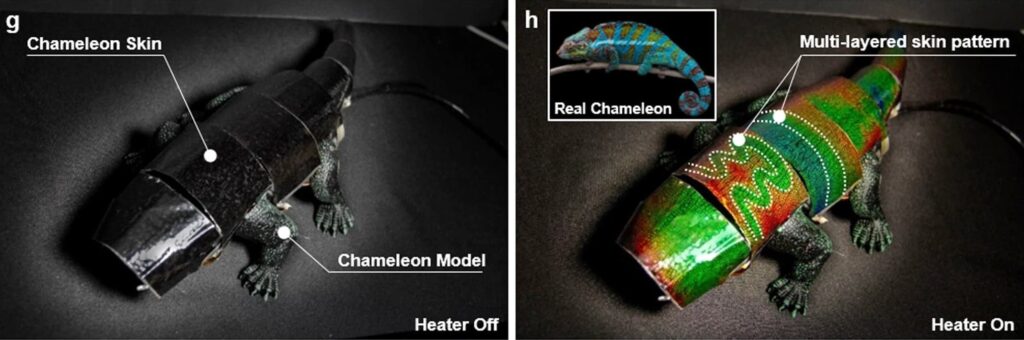

- Chameleon – Camouflage robot

- Worm – Powered by Light or Temperature

Not only animals

- Vine – Stanford

- Origami – Artificial Muscles – Origami Gripper

Its folded-up structure can lift 1,000 times its own weight and is scalable from a few millimeters to a meter long.

- Slime – Magnetic Robot

As you have noticed, most of the soft robots are university research with promising applications in multiple fields.

Advantages and disadvantages

Softness offers protection and safety.

This idea was well illustrated by the Disney film Big Hero 6, which features Baymax a health robot that can gently hug people and does not break or get damaged.

The elasticity of some soft robots allows for multiple modes of movement such as the experiment of a Harvard group that allows the ‘quadruped’ to both walk and crawl.

Soft robotics as opposed to rigid (traditional) robotics deals with robots made of soft, flexible materials such as rubber, silicone and textiles, rather than metals and plastics.

Some of the benefits of soft robotics are:

- Adaptability: Soft robots are designed to be adaptable, which means that they can be used for a wide range of tasks and in a wide range of environments. This makes them suitable for tasks requiring a high degree of flexibility or involving complex interactions with the environment.

- Safety: Soft robots are generally designed to be compliant and safe, making them suitable for tasks involving close human contact.

- Low cost: Soft robots are generally less expensive than hard robots because they require less advanced materials and technology.

- Lightweight and portable: Soft robots are generally lightweight and portable, making them suitable for tasks that require mobility or involve working in remote or hard-to-reach locations.

However, soft robots also have some disadvantages:

- Reduced precision and accuracy: soft robots are generally not as precise or accurate as hard robots, making them less suitable for tasks requiring a high degree of precision or accuracy.

- Reduced strength and durability: Soft robots are generally not as strong or durable as hard robots, making them less suitable for tasks requiring a high degree of strength or involving working in harsh environments, this can also have a positive aspect as we will see later.

- Complex programming: Soft robots often require more complex programming than hard robots, which can make them more difficult to use and programme.

Moving soft robotic parts does not allow one to know exactly what the outcome will be, but researchers at Cornell University have tried to solve this problem with a model that predicts possible actuator movements with a single fluid input in thin tubes with elastomer bellows.

University researchers are increasingly expanding the areas of soft robotics.

There are many different types of soft robots:

- Robot Gripper: In the industrial sector Soft Robotics Inc already produces Delicate Grippers for food.

Instead, these robotic grippers from ROCHU allow to grasp complicated and sensitive objects.

Another type of gripper is the Universal Jamming Grippers one that is as simple as it is effective, because compared to hard robotic fingers, the robot has not to scan the shape of the object and calculate a feasible posture to hold it.

Fields of application

- Healthcare Robots: Soft robots can be designed to conform to the shape of the human body, allowing them to be used for tasks such as surgery, rehabilitation, and assistive technology for people with disabilities.

- Wearable Robots: these biomimetic devices can be applied to a patient undergoing physical rehabilitation. The soft robot mimics the natural movement of the body wherever it is placed, helping the patient restore normal motor functions.

- Edible Robots: this exciting creation was actually invented by a high school team in Philadelphia for the annual Soft Robotics competition. These biodegradable robots can safely deliver medicine to different parts of the body.

- Soft Toy Robots: used as educational toys or as companions for children and seniors.

- Agricultural Robots: help farmers harvest crops, tend the land and inspect crops for diseases.

- Climbing Robots: these types of robots have potential applications ranging from the inspection and maintenance of buildings to search and rescue missions.

Innovative materials

Soft deformable and light, yet durable and reliable that can and when needed.

Hydrogel-based used as soft actuators and sensors.

These robots can be printed entirely in 3D Harvard Octobot soft microfluidic chips

Biodegradable materials are as promising as they are important for single-use applications and edible robotics to reduce waste, for example:

- I-Seed inspired biodegradable and intelligent robots for soil and air monitoring.

- Biogel, like sugar and jelly 3D printed robots

Credits: A. Heiden et. at the Johannes Kepler University

Other materials used in soft robotics are mainly soft, flexible and able to change shape. These include:

- Elastomers that can change shape or colour as temperature and light change

- Magnetic materials, which move in response to a magnetic field

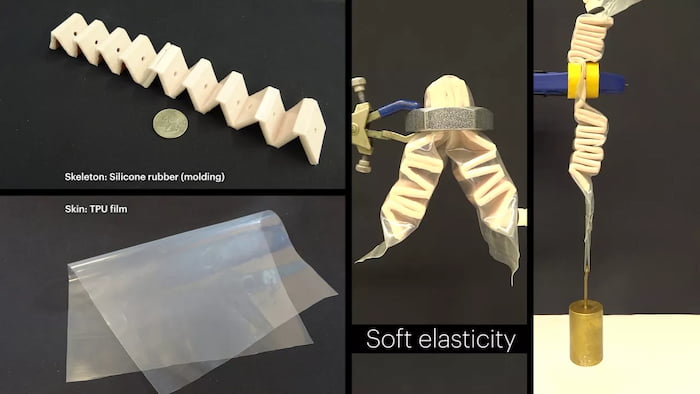

- Soft polymers such as silicone, rubber and polyurethane

- Textile materials such as non-woven fabric, knitted fabric and mesh fabric

- Soft metallic materials such as caucciù(an alloy of nickel and titanium)

- Natural materials such as natural rubber, caucho and wool

- Liquids and gases used to inflate or cool soft materials

These materials are used for the construction of soft robots and flexible drive systems.

In addition, some of these materials, such as silicone and polyurethane, are also used to create flexible and bendable sensors and electronic circuits.

Find out more about soft robotics

Here are some useful resources:

- Soft Robot Conference RoboSoft 2023

- Soft Robot Labs & Institutions – split by continent

- Soft Robot Podcast – IEEE

- Soft Robot Journal – world-class researches

- Soft Robot MIT news – Massachusetts Institute of Technology

- DIY Soft Robotics Toolkit – collection of shared resources

- DIY Soft Robotics Universal Gripper

- DIY Soft Robotics Vine

- DIY Soft Robotics Tentacle

Conclusion

From now on, not only mechatronics will deal with robots, biology, chemistry, material science, computational science will also be essential.

So new jobs will be created!

Another aspect to consider is combining rigid and soft systems will be the most effective technique to build robots that are valuable to human existence.

0 Comments